Circular vibratory finishing macnine

Circular Vibratory Finishing Machines are specially designed for processing of all types of components, from high gloss polishing to heave deburring, radiusing, chamfering, grinding, descaling, degreasing, washing...

- Compact design.

- High abrasive efficiency, good surface finishing result.

- Heavy-duty electric vibration motor.

- Adjustable vibration control.

- High durable hot-poured polyu

PLZG/PLZGC (with cured wall) without integrated screening system, features flat-bottom, for processing a wide range of components from small, middle, delicate parts to large marble slabs, which easy damaged by dam and separation screen, or for a variety of parts of different sizes and batches, where automatic unloading does not have any particular advantage.

Option:

- Variable frequency drive speed controller control for automatic operation.

- Sound-proof lid to reduce the noise

- Compound metering system and flow meter

- Magnetic separator

| PLZG |

Model |

Capacity (L) |

Power (kW) |

Dimensions LxWxH (mm) |

Weight (kg) |

|

| PLZG25 |

25 |

0.5 |

600 x 600 x 800 |

85 |

||

| PLZG50 |

50 |

1.1 |

760 x 760 x 900 |

110 |

||

| PLZG80 |

80 |

1.1 |

760 x 760 x 900 |

100 |

||

| PLZG100 |

100 |

1.5 |

1050x1050x950 |

285 |

||

| *PLZG100Z |

100 |

2.2 |

1050x1050x950 |

285 |

||

| PLZG200 |

220 |

3 |

1200x1200x1000 |

400 |

||

| PLZG300 |

260 |

3.7 |

1320x1320x930 |

600 |

||

| *PLZG300Z |

260 |

5 |

1320x1320x930 |

600 |

||

| PLZG400 |

400 |

5 |

1450x1450x1030 |

730 |

||

| PLZG480 |

480 |

5 |

1430x1430x1100 |

730 |

||

| PLZG600 |

660 |

5.5 |

1800x1800x1220 |

1300 |

||

| *PLZG600Z |

660 |

7.5 |

1800x1800x1220 |

1300 |

||

| PLZG800 |

780 |

7 |

1800x1800x1220 |

1300 |

||

| PLZG900 |

900 |

7 |

1900x1900x1450 |

2200 |

||

| PLZG1200 |

1200 |

11 |

2120x2120x1500 |

2200 |

||

| PLZG1500 |

1500 |

14 |

2120x2120x1550 |

2400 |

||

| PLZG2500 |

2500 |

18.5 |

2320x2320x1570 |

3000 |

||

| PLZGC |

Model |

Capacity (L) |

Power (kW) |

Dimensions L x W x H (mm) |

Weight (KG) |

|

| PLZGC30 |

30 |

0.5 |

600 x 600 x 810 |

100 |

||

| PLZGC80 |

80 |

1.1 |

760 x 760 x 920 |

100 |

||

| PLZGC100 |

100 |

1.5 |

1100x1100x950 |

285 |

||

| *PLZGC100Z |

100 |

2.2 |

1100x1100x950 |

285 |

||

| PLZGC200 |

200 |

3 |

1200x1200x1050 |

560 |

||

| PLZGC300 |

300 |

3.7 |

1200x1200x1000 |

560 |

||

| PLZGC300Z |

300 |

5 |

1200x1200x1000 |

560 |

||

| PLZGC350 |

345 |

5 |

1450x1450x1030 |

600 |

||

| PLZGC600 |

600 |

5.5 |

1800x1800x1220 |

1080 |

||

| PLZGC600Z |

600 |

7.5 |

1800x1800x1220 |

1080 |

||

| PLZGC900 |

900 |

9 |

1900x1900x1450 |

1800 |

||

| PLZGC900Z |

900 |

11 |

1900x1900x1450 |

1800 |

||

| PLZGC1200 |

1200 |

11 |

2120x2120x1500 |

2400 |

||

| PLZGC1200Z |

1200 |

15 |

2120x2120x1500 |

2400 |

||

| * |

suitable for steel ball burnishing |

|||||

Circular Vibratory Finishing Machines with an integrated screening system

LZG/LZGC (with cured wall,LZGS with straight wall) with an integrated screening system consisting of manually (standard option) or pneumatically activated separation flap and a built-in separation screen.Separating screen is changeable.

Manually (standard option) or pneumatically activated separate flap for automatic separation, media and components are delivered over the separation screen and the media returns through the screen to the bowl and components discharge to a collect bin or secondary operation. This series machines are suited for the processing of high production, small components, or flat, lightweight parts which easy stick together. They are also suitable for steel ball burnishing processing.

Option:

• Variable frequency drive speed controller control for automatic operation.

• Pneumatic operated separation flap for automatic operation.

• Sound-proof lid to reduce the noise

• Compound metering system and flowmeter

• In-feed chute (only for LZGS series) for connection with other machinery for automatic processing line.

• Magnetic separator

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Options:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

Tub vibratory finishing machines is suitable for processing medium and large sized delicate components with complex profile for deburring, chamferring, polishing, cleaning, burnishing, brightening, smoothing all kinds of metal, plastic and ceramic parts.

Tub vibratory finishing machine is also widely used for process marble stone to achieve antique appearance.

Feature

1. Driven by two vibratory motors, one each at the end of tub.

2. Tub can be divided into separate processing chambers by PU coated dividers to process delicate components to prevent part-on-part impact.

Options:

- VFD speed controller.

- Separate divider sheets.

- Compound pump and water flowmeter.

- Sound-proof lid.

| XZG |

Capacity L |

Tub Inter Dimension L x W x H (mm) |

PU mm |

Power kw |

Overall Dimension L x W xH (mm) |

Weight kg |

| XZG15* |

15 |

440 x 208 x 215 |

10 |

0.37 |

526 x 380x 555 |

85 |

| XZG100 |

100 |

664 x 400 x 460 |

20 |

2 x 1.1 |

1320 x 615 x 860 |

350 |

| XZG500 |

500 |

1310 x 690 x 700 |

25 |

2 x 2.2 |

2670 x 1000 x 985 |

700 |

| XZG900 |

900 |

1200 x 900 x 850 |

25 |

2 x 4.0 |

2700 x 1050 x 1100 |

900 |

| XZG1000 |

1000 |

2200 x 730 x 645 |

25 |

2 x 4.0 |

3662 x 970 x 1080 |

1600 |

| XZG1200 |

1200 |

2000 x 750 x 854 |

25 |

2 x 4.0 |

3000 x 1050 x 1100 |

2100 |

| XZG1800 |

1800 |

2020 x 1120 x 940 |

25 |

2 x 5.5 |

3500 x 1336 x 1256 |

2800 |

| XZG2800 |

2800 |

1580 x 1510 x 1270 |

25 |

2 x 9.0 |

3300 x 1830 x 1740 |

4000 |

| XZGC |

Capacity L |

Tub Inter Dimension L x D/W **x H (mm) |

PU mm |

Power kW |

Overall Dimension L x W xH (mm) |

Weight kg |

| XZG240C** |

240 |

690 x 670/524 x 625 |

16 |

2 x 1.1 |

1880 x 880 x 920 |

450 |

| XZG500C** |

500 |

1310 x670/ 524 x 625 |

16 |

2 x 2.2 |

2870 x 880 x 920 |

700 |

| XZG750C** |

750 |

2000 x/670/ 524 x 625 |

16 |

2 x 2.2 |

3354 x 880 x 920 |

800 |

| Remark |

* one motor only ** Processing tub with curved well. *** D=tub diameter, W=top open wide |

|||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Centrifugal Disc Finishing Machines | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Rotary Finishing Machine | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Ceramic Media and Porcelain Media

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Plastic Media | |||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

| Ceramic Beads | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Glass Beads for Sand Blasting | |||||||||||||||||||||||||||||||||||||||

| Glass beads have perfect spheres with a smooth, brilliant surface, chemically inert, widely used in wet or dry method for prestressing shot peening, cleaning, trimming, surface finishing, smooth and deburring processing in industrial fields of aerospace, automotive, and electronics. | |||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||

| Garnet | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Almandine garnet is a natural abrasive in dark red color, made of garnet mineral rock. It is inert and non-toxic, environmental friendly material, has a very low dust emission,which make it an ideal abrsive media for sand blasting, sand cleaning, water jet cutting, it is also suitable for lapping, making organic bonded abrasive tools, glass polishing, and used as water filtration media, etc.

|

Typical applications: |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Plastic Blasting Media

|

||||||||||||||||||

|

Plastic Blasting Media (PBCM) is designed specifically for deflashing, coating removal, paint stripping, mold cleaning and surface preparation. Engineered for high performance, PBCM is clearly the leader when it comes to productivity and value. This is sometimes called Plastic Media, PMB (Plastic Media Blassting) or Plastic Abrasives.

They are 6 kinds of Plastic Blasting Media available: Melamine Formaldehyde, Urea Formaldehyde, Polycarbonate Cryogenic, Nylon Polyamide, Acrylic , Poly Allyl Di-Glycol Carbonate. |

||||||||||||||||||

|

||||||||||||||||||

|

||||||||||||||||||

|

||||||||||||||||||

|

||||||||||||||||||

|

||||||||||||||||||

|

||||||||||||||||||

|

||||||||||||||||||

| Wet Blast Cabinet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Pressure Blast Cabinets | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Pressure blast cabinet consists of cabinet enclosure, cyclone reclaimer & blast system and dust collector for tough cleaning, peening, deburring jobs. Compared to suction blasting, pressure blasting delivers higher abrasive media velocity for greater impact intensity, and can increase production rate by as much as 300 percent.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| It's widely used for process the surface of the forged parts, casting parts, welding parts, components after heat treatment, etc.

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Features: 1. 24" long rubber gloves resist wear and protect operator. 2. Dst-proof light for extraordinary visibility. 3. Safety interlocks interrupt blasting if the door is opened. 4. Steel plate welded construction, with properly formed bends, forms a rigid, long-lasting cabinet shell. 5. Glass view window, exchangeable. 6. Pressure regulator, gauge, and electric switch mounted within easy reach. 7. One pressure blast gun with boron carbide nozzle dia 8mm. 8. Pneumatic foot pedal switch for activating blasting. 9. Built-in blow-off gun helps keep dust inside the cabinet. 10. Dry filter dust collecting, manually dust cleaning 11. Air source requirement: Pressure 8bar(kg/cm2); Flow 1.5-2m3/min. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Suction Blast Cabinets | |

| Suction blast cabinets consist of cabinet enclosure, cyclone reclaimer and dust-collector, deliver efficient, affordable blast media to clean, peen, debur, or finish metal parts, easy use, low maintenance. Blast cabinet enclose the blasting environment to provide efficient blast cleaning while maintaining a clean surrounding work area. | |

| Features: 1. 24" long rubber gloves resist wear and protect operator. 2. Dust-proof light for extraordinary visibility. 3. Safety interlocks interrupt blasting if the door is opened. 4. Steel plate welded construction. 5. Large glass view window, exchangeable. 6. Pressure regulator, gauge, and electric switch mounted within easy reach. 7. One Suction blast gun with boron carbide nozzle dia 8mm. 8. Dry filter dust collector. 9.Manually dust Cleaning, 10. Built-in blow-off gun helps keep dust inside the cabinet. 11. Pneumatic foot pedal switch for activating blasting. 12. Compressed air source:5-7 bar, 0.8-1.2 m3/min |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Options: 1. Front door or/and side door 2. Heat device for fine abrasive mesh 180-320 3. Manual turntable 4. Swing manual turntable 5. Automatic turntable 6. Work car manual or powered & track assembly 7. Reverse pulse cartridge dust collectors 8. Pneumatic vertical lift door 9. Adjustable gun moun |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

| Multistation Blast Cabinets | |||||||||||||||||||||||||

| Multi-station sand blasting machines can in suction blast machine or in pressure blast machine, have big working cabinet and 2 to 6 operation station and 2-6 blasting guns for 2-6 operators to do blasting work simultaneously, can provide easy access to blast from either station for large, long and complex parts. Product Feature: |

|

||||||||||||||||||||||||

|

|||||||||||||||||||||||||

|

|||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Granet Recycling Machine | ||||||||||||||||||

|

Garnet Recycling Systems is used to reclaim and separate granular material. Main function is to remove all coarse contaminations like nails, nuts, stones, welding rod ends, cigarette butts, broken glass, wood, extract dust to get reusable material. The system consists of inlet port, bucket elevator, screw conveyor, air separator, vibratory screen,sand hopper, cartridge filter dust collector with automatic reverse pulse dust cleaning, and electrical control system etc. |

||||||||||||||||||

|

The contaminated abrasive garnet is loaded into the feed port, and then it is picked up by the bucket of the elevator and raised up by elevator and dropped into the inlet chute to the rotating screen.

The internal screw of the rotary screen remove the large contaminates to the end for disposal. Particles small than 4.8mm fall through the rotary screen mesh and form a curtain, falling onto the vibrating screen. Air current generated by the built in dust collector are introduced to create a simple air wash. Bu adjusting the air flow, the amount of the undersized material or fines removed can be controlled. The dusty air is then drawn to the dust collector and the fines drop into the disposal container. The garnet then falls through the vibratory screen. The particles small than 0.7mm will pass through this screen, and collected in the hopper below and can be emptied into a bulk bag or drum. |

|

|||||||||||||||||

|

||||||||||||||||||

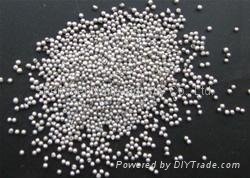

Stainless Steel Shots are widely used for deburring and brightening of the surface of aluminium alloy, zinc alloy, colorful metal and stainless steel, etc. They are of austenite structure with execellent features of high strengh and tough, low consumption, none dust, quick clean speed and good clean results. They can extend fatigue life, enhance corrosion- resisting and brighten the surface of parts. The hardness for new material state is appro 300HV, for usage state is about 450HV. Its specific gravity is 7.8g/cm3 and bulk density is 4.7g/cm3.

Physical & Chemical Specification.

C =0.15-0.20%

Si=1.5-2.5%

Mn=0.9-1.2%

Ni=7.0-10.0%

Cr=16-20%

Other

Remark: Hardness: Before Use HV-250

After Use HV-450

Product Specification/Models

S10: 0.05-0.2 mm

S20: 0.1-0.3 mm

S30: 0.14-0.5 mm

S40: 0.4-0.8 mm

S50: 0.6-1.0 mm

S60: 0.7-1.25 mm

S100: 1.00-1.40 mm

S150: 1.25-1.7 mm

S200: 1.4-2.0 mm

S300: 1.7-3.0 mm

Overhead rail spin hanger(s) shot blasting machine are specially suitable for the treatment of sensitive parts, particularly complex, heavy, or large metal castings or forging parts without part-on-part contact possible. The parts are mounted on a hook and transported into the blasting chamber.

Multiply highly efficient blast wheels fixed on the machine housing make it possible to treat the components on all sides.

The rotating of the hanger(s) ensure that the blasting media, accelerated by the blast wheels, reache every component, providing the best possible uniform blasting result.

|

|||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

high quality Zinc cut wire, aluminium cut wire, stainless steel cut wire and copper cut wire from China at competitive price and excellent service.

Zinc cut wire, Aluminium cut wire and aluminium cut wire are widely used for shot peening to give compressive residual stress in the surface layer of components for fatigue life enhancement and suppression of stress corrosion cracking and deburring and cleaning of zinc or aluminum die cast parts without any damage to the parts, and creating much less dust than natural and artificial corundum abrasives.

Available sizes:

Zinc Cut Wire: 0.8mm, 1.0mm, 1.2mm, 1.5mm, 1.8mm, 2.0mm, 2.5mm

Conditioned Zinc Cut Wire: 0.6mm, 0.7mm, 0.8mm, 1.0mm, 1.5mm, 2.0mm, 2.5mm

Aluminium Cut Wire:0.6mm, 0.7mm, 0.8mm, 1.0mm, 1.5mm, 2.0mm, 2.5mm

Copper Cut Wire:0.6mm, 0.8mm, 1.0mm, 1.5mm, 2.0mm, 2.5mm

Stainless Steel Cut Wire is widely used for shot peening to give compressive residual stress in the surface layer of components for fatigue life enhancement and suppression of stress corrosion cracking as well as cleaning and polishing of the surface of metal parts, deburring of die cast parts, is of reusable and recyclable, the working life is 1000 times of glass bead. Stainless steel cut wire can produce very bright surface, but creat much less dust than glass beads, natural and artificial corundum abrasives. The hardness is 20-40HRC.

Available sizes: 0.2, 0.3, 0.4, 0.5, 0.6, 0.8, 1.0, 1.2, 1.5, 2.0, 2.5mm.

If you are interested in this item, please feel free to contact us.

.jpg)

.jpg)